Formic Acid 85%

Specification

Formic Acid Content 85%,

Liquid Form,

Specific Gravity (SG)

Content

Formic Acid as HCOOH 85% (min),

Iron (Fe) 5 ppm (maks),

Lead (pb) 5 ppm (maks),

Sulfate (SO4) 10 ppm (maks),

Chloride (Cl) 20 ppm (maks)

Usage

Textile Industry,

Leather Industry,

Cleaning Material,

Pharmacy,

Oil Drilling,

Dll

Packaging

Jerrycan 25Kg, Jerrycan Gray Color,

IBC 1000KG,

Tankers

Formic Acid 90%

Spesification

Formic Acid Content 90%,

Liquid Form,

Specific Gravity (SG)

Content

Formic Acid as HCOOH 90% (min),

Iron (Fe) 5 ppm (maks),

Lead (Pb) 5 ppm (maks),

Sulfate (SO4) 10 ppm (maks),

Chloride (Cl) 20 ppm (maks)

Usage

Textile Industry,

Leather Industry,

Cleaning Material,

Pharmacy,

Oil Drilling,

Dll

Packing

Jerrycan 25Kg, Jerrycan Gray Color,

IBC 1000KG,

Tankers

Formic Acid 94%

Spesification

ormic Acid Content 94%

Liquid Form,

Specific Gravity (SG)

Content

Formic Acid as HCOOH 94% (min),

Iron (Fe) 5 ppm (maks)

Lead (Pb) 5 ppm (maks),

Sulfate (SO4) 10 ppm (maks),

Chloride (Cl) 20 ppm (maks)

Usage

Textile Industry,

Leather Industry,

Cleaning Material,

Pharmacy,

Oil Drilling,

Dll

Packing

Jerrycan 25Kg, Jerrycan Gray Color,

IBC 1000KG,

Tankers

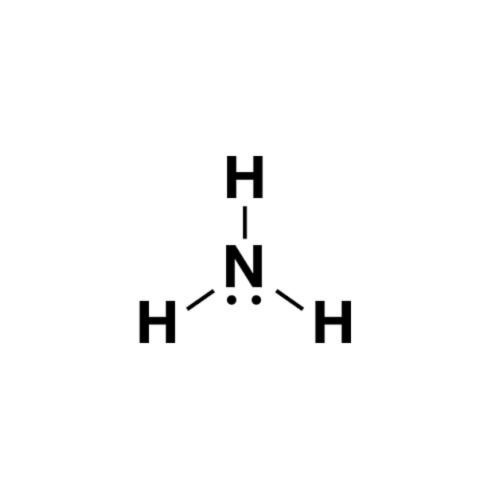

Below Are The Uses Of Ammonia 99%

Ammonia is usually used as a drug, a mixture of urea (CO(NH2)2) and ZA (Zwvelamonia) ((NH4) 2SO4) fertilizers, ammonium chloride (NH4Cl) in batteries, nitric acid (HNO3), refrigerants, making hydrazine (N2H4) as rocket fuel, the basic material for making explosives, plastic paper, and detergent and if dissolved in water, the substance will be able to clean household appliances

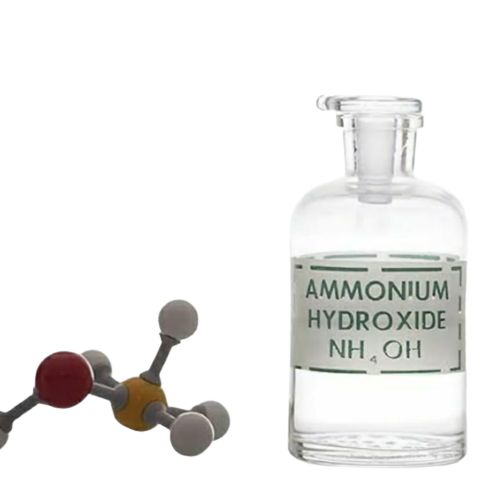

Aqueous Ammonia 25%

-PT Sintas Kurama Perdana produces aqueous ammonia with a minimum content of 25%

-Production capacity reaches 40 tons / day

-PT Shintas Kurama Perdana was appointed as distributor of 25% liquid ammonia produced by PT Pupuk Kujang with a production capacity of 100 tons / day. So PT Perdana Bone Syntes' total aqueous ammonia production reaches 140 tons / day

Learn More

liquid CO2

-PT Sintas Promo Perdana was appointed as distributor of liquid CO2 produced by PT Pupuk Kujang with a guaranteed supply of 7000 tons / year -The liquid CO2 produced has an FSC 22000 certificate and a halal certificate

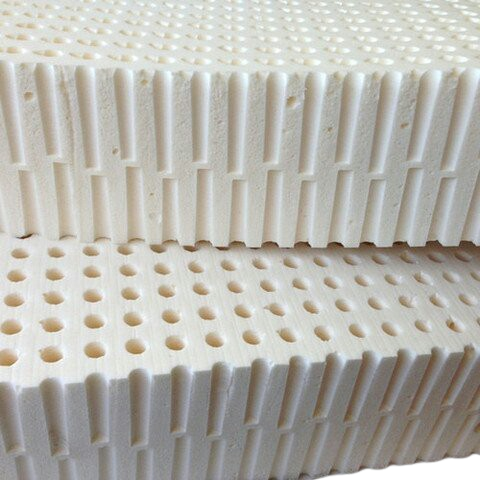

Natural Rubber Coagulant

Coagulation is the first crucial step in the processing of natural rubber (NR) that happens naturally or is induced by various techniques. The mechanism of Hevea latex coagulation involves the destabilization and aggregation of latex particles that are influenced by different factors.

There are approximately 2000 species of latex bearing plants globally, with more than about 1000 of them producing a high content of cis-1,4-polyisoprene in milky colloidal dispersion system, or most known as Natural Rubber (NR) (Greve, 2000). Among all the plant species mentioned, Hevea brasiliensis is renowned to be one of the most important sources of NR for the industry. Typically, fresh Hevea latex contains 35% of rubber hydrocarbon and 5–6% of non-rubber components comprising lipids, proteins, carbohydrates, and minerals. Fresh latex is almost neutral with pH 6.5–7.0 and Dried Rubber Content (DRC) ranges 25–50% by weight (Priyadarshan, 2011). After the tapping process, the latex is subjected to various processing steps converting it to a suitable phase for the need of respective industries

Dyeing Textile

Used in the leather tanning process as a lime cleaning agent and pH regulator during dyeing

6Dyeing is the application of dyes or pigments on textile materials such as fibers, yarns, and fabrics with the goal of achieving color with desired color fastness. Dyeing is normally done in a special solution containing dyes and particular chemical material. Dye molecules are fixed to the fiber by absorption, diffusion, or bonding with temperature and time being key controlling factors. The bond between dye molecule and fiber may be strong or weak, depending on the dye used. Dyeing and printing are different applications; in printing, color is applied to a localized area with desired patterns. In dyeing, it is applied to the entire textile

The primary source of dye, historically, has been nature, with the dyes being extracted from animals or plants. Since the mid-19th century, however, humans have produced artificial dyes to achieve a broader range of colors and to render the dyes more stable to washing and general use. Different classes of dyes are used for different types of fiber and at different stages of the textile production process, from loose fibers through yarn and cloth to complete garments.

Learn MoreTanning Leather

Used as a PH acid regulator in the whitening and dyeing process

Tanning is the process of treating skins and hides of animals to produce leather. A tannery is the place where the skins are processed.

Tanning hide into leather involves a process which permanently alters the protein structure of skin, making it more durable and less susceptible to decomposition and coloring.

Before tanning, the skins are dehaired, degreased, desalted and soaked in water over a period of six hours to two days. Historically this process was considered a noxious or "odoriferous trade" and relegated to the outskirts of town. Historically, tanning used tannin, an acidic chemical compound from which the tanning process draws its name, derived from the bark of certain trees. An alternative method, developed in the 1800s, is chrome tanning, where chromium salts are used instead of natural tannins.